For many years, man has been working with machines to produce electronic equipment, machinery, vehicles and other electrical products. Most factories are made up of machines that operate day and night. Industry has come a long way since machines were introduced to reinforce production, manufacturing, design and other industrial chains. This also applies to small businesses and workshops, in any field of activity. However, these machines are not without risk. The energy that powers them, and in particular the energy they give off (statistical electricity), can have serious health consequences. What is static electricity? How does it form? How can we prevent and protect against it? NeoSol, the flooring specialist, answers your questions and presents its solution: ESD mats.

What is static electricity and how is it generated?

We've all experienced a "jolt" or spark when touching electronic objects. It's called an electric discharge and is caused by static electricity. This phenomenon is created when 2 insulating materials are rubbed against each other. One of them will pull some of the electron charge from its atoms towards it. Its charges can then stagnate for a few minutes to several days, and when you put your hand on it, you may get a small electric shock. This will have no effect on your health, as it measures only 20 to 30 kilovolts. They most often occur in an environment with a high electrical charge, such as in industry. The risk here is much greater, and can be dangerous for employees constantly working in a high-risk zone.

Why can it be dangerous for employees?

The release of electrons from electrical machines, which form static shocks, should not be underestimated. Although invisible, they can be lethal in certain situations. The build-up of static electricity on equipment or other insulating surfaces can be a real danger if the charges don't drain away. Fire, explosion and electric shock are the main risks to which employees working in electrical or explosive areas are exposed. The rate of occupational accidents due to electricity fell by 74% between 1962 and 2000, thanks to the introduction of a decree to reduce this risk. Since then, numerous measures have been put in place to enable employees to work in a safer environment. Nevertheless, the risks remain, and accidents still occur: injuries, burns and even fatalities. In addition to the human risk, electrostatic discharges can cause major material hazards.

The important thing to remember is that static electricity is annoying for humans, but not dangerous. It's only in high-risk areas or the combination of this energy with other components that can have serious consequences.

For example:

- Use of faulty or unapproved equipment/machinery

- Use of explosive or flammable agents.

- Working on live machines.

- Lack of training and information on the use of electrical machines and equipment.

Prevent this risk with ESD Mats

Like all risks, there is a need for prevention and the implementation of measures to avoid and eliminate them. Prior to this stage, a study and analysis of each workstation and of the equipment made available to employees is carried out to measure their hazardousness. This enables solutions to be tailored to each workstation and working environment.

For the risk of static electricity, there are several measures.

- Reduce the electrical charge released by equipment with ESD mats

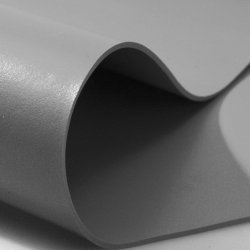

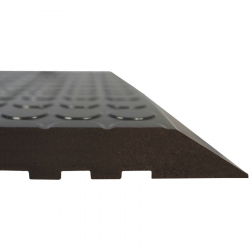

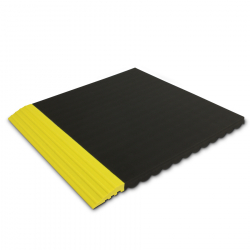

Professional floor coverings are essential preventive equipment for companies. Whatever the sector of activity, there is a suitable preventive mat for every problem and every risk. NeoSol offers several ranges of floor mats, one of which is the ESD mat specially designed to stop electrostatic discharges.

The ESD mat is a dissipative mat, which means it evacuates electrical build-up from machines and other electronic equipment while preventing the transmission of electricity. It therefore protects employees from shocks, enabling them to work safely in high-risk areas or environments. It also protects your electrical equipment from fire or ignition.

- Protecting yourself with personal protective equipment

In some companies or industries, the use of safety footwear is an obligation in order to be able to work. This is the case for jobs involving electrical hazards. In addition to this PPE, antistatic clothing and gloves must be worn to protect against electric shock.

- Replacing defective or non-compliant equipment

All machines and tools used by employees, whether materials handlers or other workers, must comply with the relevant regulations. Inspections must be carried out to guarantee their efficiency and safety. It is also advisable to replace insulating equipment with machines that do not conduct static electricity, to eliminate any risk.

![Fire classification, UPEC and ISO 10874 standards Fire classification, UPEC and ISO 10874 standards]() Fire classification, UPEC and ISO 10874 standardsFire rating and quality standards should be one of the main criteria to consider before buying professional flooring. Find out why with NEOSOL.Read More

Fire classification, UPEC and ISO 10874 standardsFire rating and quality standards should be one of the main criteria to consider before buying professional flooring. Find out why with NEOSOL.Read More![Static electricity risks and solutions Static electricity risks and solutions]() Static electricity risks and solutionsHow dangerous is static electricity for employees? How do industries reduce the risks associated with electrostatic discharge?Read More

Static electricity risks and solutionsHow dangerous is static electricity for employees? How do industries reduce the risks associated with electrostatic discharge?Read More![Professional mats: how to care for them? Professional mats: how to care for them?]() Professional mats: how to care for them?Professional mat maintenance is essential to maintain the longevity of your mat and the safety of passers-by. NEOSOL, the flooring expert, reveals its different maintenance methods.Read More

Professional mats: how to care for them?Professional mat maintenance is essential to maintain the longevity of your mat and the safety of passers-by. NEOSOL, the flooring expert, reveals its different maintenance methods.Read More![Accessibility and ERP: how do I know if I'm in compliance? Accessibility and ERP: how do I know if I'm in compliance?]() Accessibility and ERP: how do I know if I'm in compliance?Accessibility must be a priority for every ERP. But you still need to know if you're in compliance. To help you, NeoSol, the professional flooring specialist, tells you more.Read More

Accessibility and ERP: how do I know if I'm in compliance?Accessibility must be a priority for every ERP. But you still need to know if you're in compliance. To help you, NeoSol, the professional flooring specialist, tells you more.Read More

Leave a comment