In industry, and more specifically in the food industry, quality management is a fundamental pillar. Highly governed by health and safety standards, quality management aims to provide strategic organization to maintain impeccable hygiene on the premises. It also oversees the entire transformation process, from the arrival of raw materials to the delivery of finished goods.

Understanding quality management and its associated regulations is of vital importance to the food industry. That's why NEOSOL, experts in the sale of floor coverings for professionals, explains what quality management is all about, what standards need to be met, and how to maintain quality with an innovative device called ProfilGate. But first, we explain why food safety and hygiene are a major issue in this sector.

Food safety and hygiene: major challenges for the food industry

Guaranteeing food hygiene and safety are major challenges facing food production companies. For many years now, manufacturers have been facing major issues that can impact on consumer health and safety. Producing food in an industrial setting entails risks, particularly when it comes to cleaning and disinfecting industrial machinery. The equipment and tools used can be a source of microbiological and chemical contamination and infection. According to a 2018WHO publication, more than 200 diseases are transmitted through food, meaning that 1 in 10 people fall ill every year as a result of contaminated food.

To combat these major public healthissues , the agri-food industries have had to put in place a set of measures and rules to ensure food safety throughout the production chain. This is known as quality management.

What is quality management?

Also known as a quality management system, quality management is a set of methods, standards and objectives designed to improve or increase an organization's production quality. This system takes the form of a quality approach that concerns all levels of a company, whether food or non-food. All departments are involved, from communications to production, from sales to human resources and logistics. It can be managed internally by each department, or across the board by all departments.

ISO standards

Quality management systems are governed by standards issued by theInternational Organization for Standardization (ISO). Several standards apply, such as ISO 9000 and ISO 22000. They establish a guideline for the agri-food industry and other food-producing sectors. These standards aim to improve product quality, maintain site hygiene and set up a food safety management system to ensure that consumers benefit from a quality product.

ISO standards are not mandatory for companies, but can be applied on a voluntary basis. ISO certificates are valid for 3 years, and can be renewed after an audit.

Other industrial food hygiene standards

Other standards, labels or methods linked to food safety and production site hygiene can be implemented as part of your quality management strategy.

Indeed,we have the HACCP (Hazard Analysis and Critical Control Point) method, which studies hazards and defines critical control points for food safety. Defined by the Codex Alimentarius, this study is compulsory for food companies. This method includes the GBPH (Guide de Bonnes Pratiques d'Hygiène - Good Hygiene Practices Guide), drafted by food industry professionals and registered by an interprofessional union in the Journal Officiel.

Recognized in France and Germany, the IFS (International Food Standard) is a set of regulations designed to guarantee food safety. It is primarily intended for manufacturers of private label food products. For UK retailers, there is also a standard called BRC (British Retail Consortium Standard).

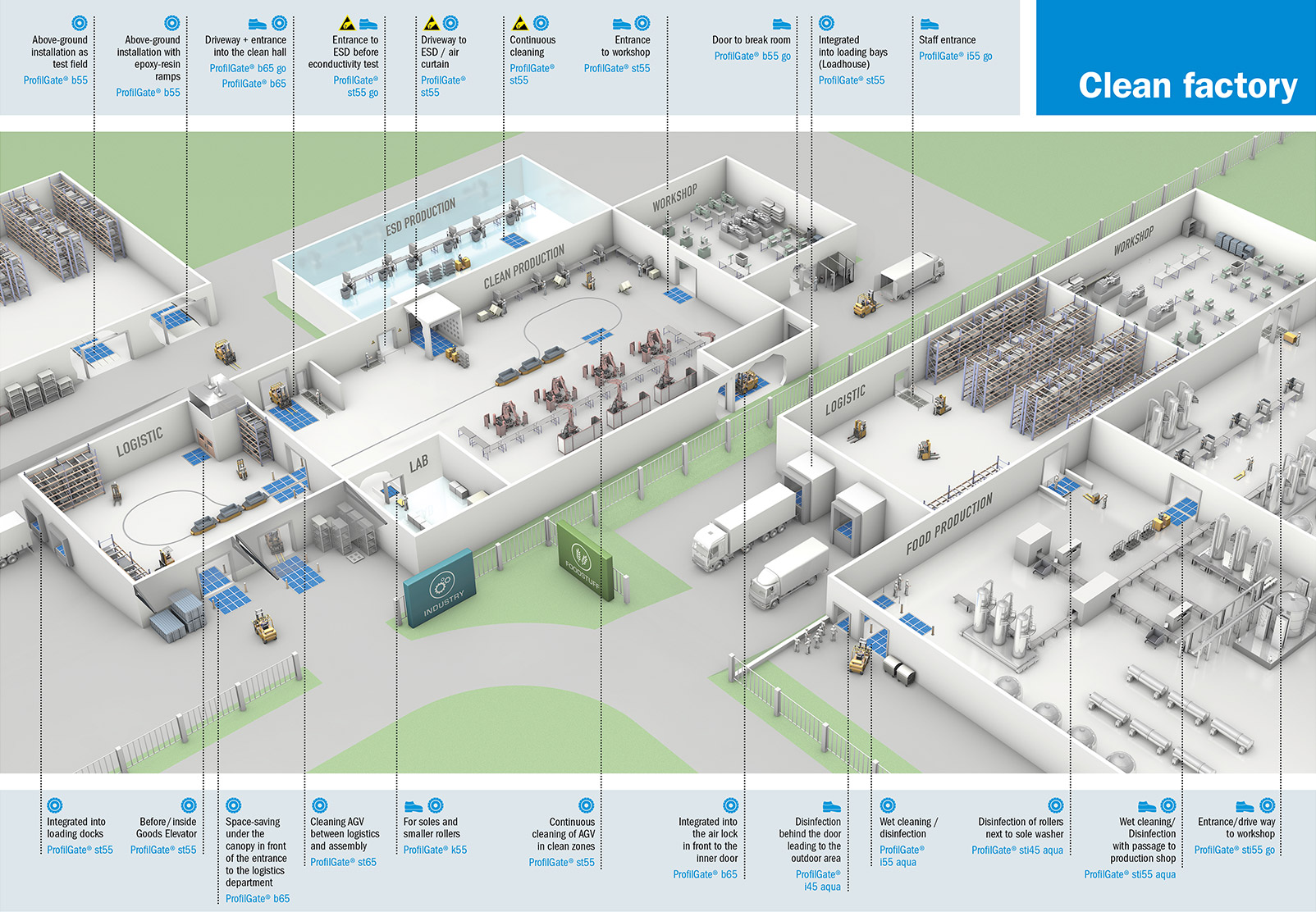

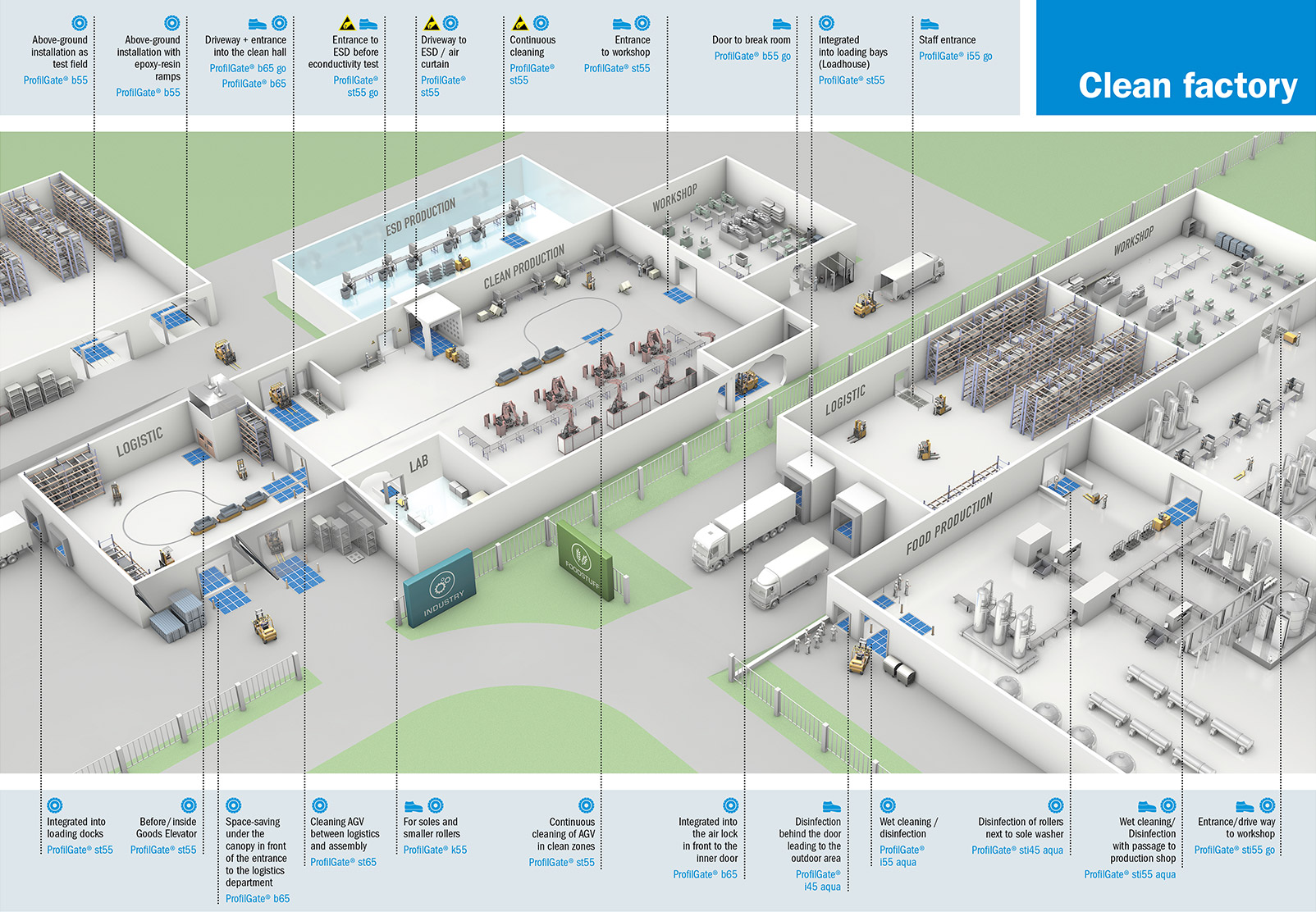

ProfilGate: a cleaning and disinfection system for manufacturers

Aware of the risks that consumers and manufacturers face on a daily basis, industrial cleaning professionals have developed and designed an innovative floor cleaning and disinfection system called ProfilGate.

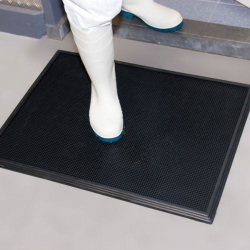

This patented and certified innovation responds to a problem encountered by many industries and which is the point of entry for bacteria: the tires and wheels of vehicles or carts. Indeed, to transport or move raw materials or finished products from outside to inside the building or between 2 departments, employees use vehicles or carts adapted to this environment. To clean their wheels, the vehicles pass over the ProfilGate floor covering.

With its concave brush strips and alternating 30-degree bristle inclination, ProfilGate removes up to 90% of impurities and dirt from tire and wheel surfaces.

The different ProfilGate ranges

To meet and adapt to every situation, the ProfilGate has several ranges to suit both wheels and employee soles. You can choose between :

- ProfilGate b and st: for dry-cleaning of wheels in high-influence areas such as production, assembly, shipping, etc.

- ProfilGate i, sti, k: wheel cleaning for specific situations in the food and beverage industries, etc.

- ProfilGate i aqua, sti aqua: wet cleaning and disinfection of wheels or shoe soles in the food, chemical and pharmaceutical industries, etc.

- ProfilGate b go, st go: cleaning of soles in storage, production and shipping halls only.

- ProfilGate i go, sti go: for cleaning the soles of passers-by in specific sites such as the dairy, sugar or meat industries .

6 reasons to invest in a ProfilGate

Investing in a ProfilGate cleaning and disinfecting device may come at a price, but it will enable you to:

1. Achieve optimum industrial cleanliness on a continuous basis.

2. Create hygienic barriers between departments.

3. Enhance workplace safety by reducing employee and cart slipping due to ice during winter periods.

4. Reduce dust deposits on food in storage areas.

5. Significantly reduce the cost of cleaning your floors.

6. Reduce the cost of renovating floors due to the transport of impurities in wheels or soles.

Ask for a quote now!

NEED ADVICE?

Contact Solène

![Fire classification, UPEC and ISO 10874 standards Fire classification, UPEC and ISO 10874 standards]() Fire classification, UPEC and ISO 10874 standardsFire rating and quality standards should be one of the main criteria to consider before buying professional flooring. Find out why with NEOSOL.Read More

Fire classification, UPEC and ISO 10874 standardsFire rating and quality standards should be one of the main criteria to consider before buying professional flooring. Find out why with NEOSOL.Read More![Static electricity risks and solutions Static electricity risks and solutions]() Static electricity risks and solutionsHow dangerous is static electricity for employees? How do industries reduce the risks associated with electrostatic discharge?Read More

Static electricity risks and solutionsHow dangerous is static electricity for employees? How do industries reduce the risks associated with electrostatic discharge?Read More![Professional mats: how to care for them? Professional mats: how to care for them?]() Professional mats: how to care for them?Professional mat maintenance is essential to maintain the longevity of your mat and the safety of passers-by. NEOSOL, the flooring expert, reveals its different maintenance methods.Read More

Professional mats: how to care for them?Professional mat maintenance is essential to maintain the longevity of your mat and the safety of passers-by. NEOSOL, the flooring expert, reveals its different maintenance methods.Read More![Accessibility and ERP: how do I know if I'm in compliance? Accessibility and ERP: how do I know if I'm in compliance?]() Accessibility and ERP: how do I know if I'm in compliance?Accessibility must be a priority for every ERP. But you still need to know if you're in compliance. To help you, NeoSol, the professional flooring specialist, tells you more.Read More

Accessibility and ERP: how do I know if I'm in compliance?Accessibility must be a priority for every ERP. But you still need to know if you're in compliance. To help you, NeoSol, the professional flooring specialist, tells you more.Read More

Leave a comment