Occupational hazards are, and always will be, present in all sectors of activity. Some are minor risks, while others are much more significant. There are more than 1,000 known risks that employees face on a daily basis. According to the French National Health Insurance, the number of work-related accidents rose by 6% from 2018 to 2019, i.e. more than 655,715 new recognized claims.

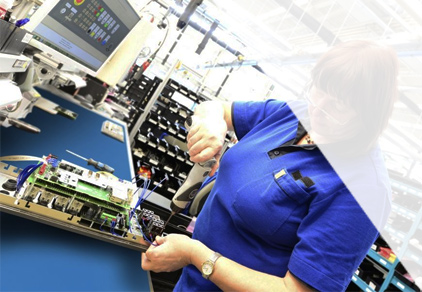

Some of these occur in the chemical or electrical industries. Numerous means of prevention are in place to ensure the protection of personnel. But to know what these means and preventive tools are, it is essential to know the different types of electrical and chemical risks, and their degree of danger, in order to establish solutions adapted to each situation.

In this article, NEOSOL explains what chemical and electrical hazards can be, and how to prevent them.

Chemical risk: an existing but little-known hazard

INRS has defined chemical risk as any chemical substance that can lead to dangerous situations for humans and the environment.

This risk is the second leading cause of occupational illness in France. Every year, some 1,800 occupational cancers are recognized, 1,400 of them due to asbestos (source: ameli.fr). In another study carried out in 2012 by IFOP, it is stated that 89% of companies use and handle chemicals, and the1st people impacted by the hazardous nature of these products are employees. In fact, 1 in 3 employees will say they have been exposed to a chemical hazard in the workplace.

Chemical products have an impact on health if they are inhaled, ingested or come into direct contact with the skin. It is therefore essential for all employees to be aware of the chemical risks to which they may be exposed at their workstations.

Electrical risk: invisible but deadly

As its name suggests, electrical risk is caused by the primary energy used in our society: electricity. This indispensable source of energy enables a company to function properly. However, electricity causes a large number of workplace accidents every year, and only over 700 of these are reported, i.e. 0.11% of the total number of accidents. This fatal risk can be present in any situation if individual and collective protection measures are not put in place. In fact, it is mainly in the industrial and construction sectors that the risk is highest. It can be caused by direct contact, indirect contact due to a short-circuit, or by an electric arc (high-voltage lines).

These alarming figures clearly show that chemical and electrical hazards have serious consequences and are a matter of public health concern. That's why it's essential for every company to take action to reduce or eliminate these risks.

How to prevent risks?

Preventing occupational hazards requires first and foremost an assessment of employees' workstations, the equipment and tools at their disposal, and the working environment.

Also known as the EvRP, this assessment is mandatory and is the employer's responsibility. It is set out inarticles L.4121-2 and L.4121-3 of the French Labour Code.) This assessment will enable :

- identify risks and classify them in order to assess how dangerous they are ,

- eliminate all risks (minor and major) wherever possible,

- replace hazardous equipment, products or other items,

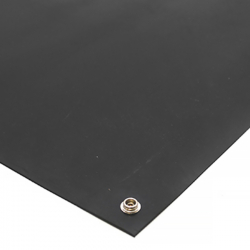

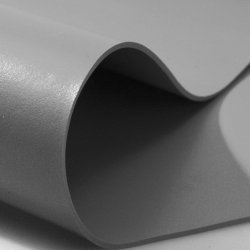

- give priority to collective protection measures for each workstation (anti-fatigue mats, ESD mats, ventilation, sanitation, etc.).

- Inform and train employees about the risks they may face and the preventive measures in place and to be taken .

Once this assessment has been carried out, each company will have to put in place solutions to enable every employee to work with greater peace of mind and greater safety.

Professional mats: NeoSol's immediate and durable solution

To provide a solution to the various risks encountered by professionals in the workplace, protective equipment has been designed by specialists in ergonomics and workplace safety. Indeed, thanks to the use of professional floor mats as a means of prevention in companies where chemical and electrical hazards are present, many employees can work in good conditions on a daily basis.

Each of the mats we offer responds to one or more problems encountered in your workplace.

You have the :

You can find out more about our professional floor mats through our blog posts or by contacting us for more information or a quote request.

Also read: ESD mats for professionals: The complete guide

NEED ADVICE?

Contact Solène

![Fire classification, UPEC and ISO 10874 standards Fire classification, UPEC and ISO 10874 standards]() Fire classification, UPEC and ISO 10874 standardsFire rating and quality standards should be one of the main criteria to consider before buying professional flooring. Find out why with NEOSOL.Read More

Fire classification, UPEC and ISO 10874 standardsFire rating and quality standards should be one of the main criteria to consider before buying professional flooring. Find out why with NEOSOL.Read More![Static electricity risks and solutions Static electricity risks and solutions]() Static electricity risks and solutionsHow dangerous is static electricity for employees? How do industries reduce the risks associated with electrostatic discharge?Read More

Static electricity risks and solutionsHow dangerous is static electricity for employees? How do industries reduce the risks associated with electrostatic discharge?Read More![Professional mats: how to care for them? Professional mats: how to care for them?]() Professional mats: how to care for them?Professional mat maintenance is essential to maintain the longevity of your mat and the safety of passers-by. NEOSOL, the flooring expert, reveals its different maintenance methods.Read More

Professional mats: how to care for them?Professional mat maintenance is essential to maintain the longevity of your mat and the safety of passers-by. NEOSOL, the flooring expert, reveals its different maintenance methods.Read More![Accessibility and ERP: how do I know if I'm in compliance? Accessibility and ERP: how do I know if I'm in compliance?]() Accessibility and ERP: how do I know if I'm in compliance?Accessibility must be a priority for every ERP. But you still need to know if you're in compliance. To help you, NeoSol, the professional flooring specialist, tells you more.Read More

Accessibility and ERP: how do I know if I'm in compliance?Accessibility must be a priority for every ERP. But you still need to know if you're in compliance. To help you, NeoSol, the professional flooring specialist, tells you more.Read More

Leave a comment